The Role and Types of Sucker Rod

The Sucker Rod is an elongated rod of the pumping well, which is connected to the polished rod and is connected to the pump to transmit power. Sucker rod: length is mostly 6 meters. The material is usually hard chrome plated on the surface of high carbon steel. It is connected with the internal thread hoop in the oil pipe and extends to the piston at the underground oil layer. Reciprocating to pump oil.

- Ordinary sucker rod: C, D, K, KD grade sucker rod.

- High-strength sucker rod: Class H, divided into HY and HL.

- Special sucker rod: hollow sucker rod: steel rod.

- Continuous sucker rod: steel rod.

- Sucker rod for screw pump: taper thread sucker rod, plug-in sucker rod.

- FRP sucker rod: fiber reinforced plastic sucker rod.

- Flexible sucker rod: carbon fiber composite sucker rod, wire rope sucker rod.

- Other types of sucker rods: electric sucker rods.

Sucker rod is an important part of the rod pumping equipment. The sucker rod is connected to the sucker rod column through a part named coupling, and the upper rod is connected to the pumping unit through light rod, the plunger of pumping pump is connected to the bottom, with function of transmiting the reciprocating motion of the ground pumping unit to the downhole oil pump.

Sucker Rod Application

The single length of the sucker rod is 7.6 or 8 meters, and can also be customized according to customer requirements. The material is generally hard chrome plated on the surface of high carbon steel. It is connected with the internal thread hoop in the oil pipe and extends to the piston at the underground oil layer. The oil is pumped by reciprocating motion. The current length of the oil well is generally about two kilometers. Take Shengli Oilfield as an example, the deepest is more than 3,000 meters.

Coupling Sleeve for Connecting 2 Sucker Rods

Sucker rod couplings, as the name implies, are couplings for connecting two sucker rods. The rods of the sucker rods are threaded at both ends. The rods of different diameters can be combined according to the needs. According to the structural features, they are divided into common couplings, reducers and special couplings.

Features of Sucker Rod Coupling

Made of high quality carbon structural steel. It has the characteristics of being difficult to rust and not easy to corrode. The connection is safe and reliable, and the construction is convenient.

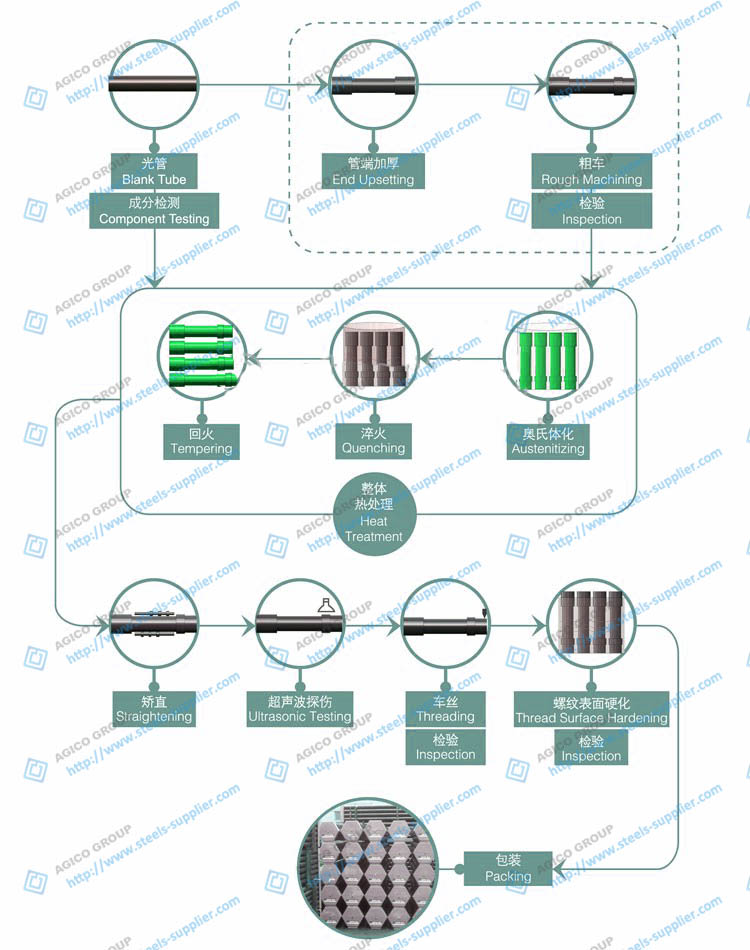

Manufacturing Processes of the API 11B Sucker Rod

Rod Test – Straightening – Non-Destructive Inpection – Friction welding – Heating – Thermal Straightening – Impeller Blasting – Ends Threading – Assembly – Anti-Corrosion – Packing – Warehousing

Sucker Rod Packaged for Delivery

Physical Property of Sucker Rods

| Physical Property of Sucker Rods | |||||

|---|---|---|---|---|---|

| Grade | Tensile Strength RmMpa | Yield Strength RelMpa | Elongation A 200mm % | ReductionZ % | Izod Impact(Type Z)J |

| C | 620~795 | ≥415 | ≥13 | ≥50 | ≥80 |

| K | 620~795 | ≥415 | ≥13 | ≥60 | ≥115 |

| D | 795~965 | ≥590 | ≥10 | ≥50 | ≥60 |

| KD | 795~965 | ≥590 | ≥10 | ≥50 | ≥60 |

| HL(eq.N97) | 965~1195 | ≥795 | ≥10 | ≥45 | ≥60 |

| HY | 965~1195 | HRC≥42;HB≥224;The depth of the hardened layer is 5% ~ 13% of the diameter of the rod body. | |||

Specifications of Sucker Rods

| Specifications of Sucker Rods | |||||

|---|---|---|---|---|---|

|

Size |

Rod Sizemm | Dia of Shouldermm | Threadin | Lengthmm | Pony Rod Lengthmm |

| 5/8 | φ15.88 | 31.8 | 15/16 |

7,620-9,140 |

508 |

| 3/4 | φ19.05 | 38.1 | 1 1/16 | 1118 | |

| 7/8 | φ22.23 | 41.3 | 1 3/16 | 1727 | |

| 1 | φ25.40 | 50.8 | 1 3/8 | 2337 | |

| 1 1/8 | φ28.58 | 57.2 | 1 9/16 | 2946 | |

Specifications of Hollow Sucker Rods

| Specifications of Hollow Sucker Rods | ||||||||

|---|---|---|---|---|---|---|---|---|

|

Model |

Rod Body | Adaptor OD. | Wrench Square |

Thread Size(mm) |

Length(mm) | |||

| (mm) | (mm) |

Rod |

Pony Rod |

|||||

| Dia. | Wall Thickness | (mm) | Length | Width | ||||

| KG32 | φ32 | 5 | 48 | 34 | 41 | 1-7/16″ | 7000~10000 | 600 |

| 1000 | ||||||||

| 1500 | ||||||||

| 2000 | ||||||||

| 3000 | ||||||||