Strain aging embrittlement of cracking cases

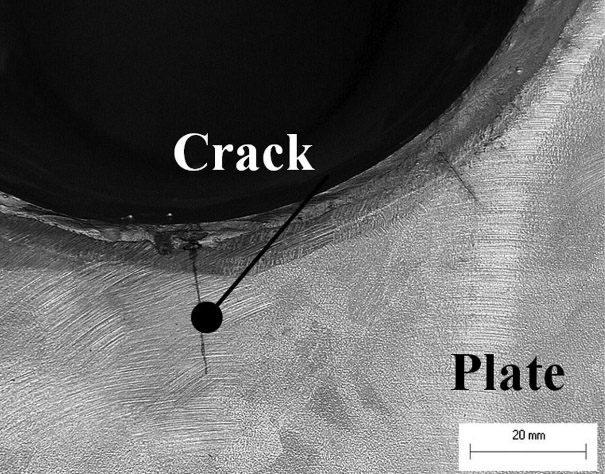

Hot problems often occur in a variety of problems, such as cracking of welds, cracking of materials, etc. Users usually don't know what's going on. In fact, the heat process can also cause cracking, because the material becomes "fragile" during heat. In the most typical case, in the case of perforated components, the steel cracks along the punched position during hot-dip galvanizing:

This kind of cracking at the position of the perforation or the edge of the galvanizing steel sheet, when it is hot-dip galvanized, it is a strain-aged brittle crack.

Causes of strain aging cracking

In the galvanizing process, there are two possible cases of strain aging fracture:

- Before galvanizing, the stress must be “introduced”. Cold working operations such as punching, grooving, shearing, and severe bending may cause "stress" inside the steel. If stress relief is not applied prior to galvanizing, the stress introduced into the material during the galvanizing process will translate into high local residual stresses and will result in strain aging brittleness.

- Strain aging brittleness may also be caused by inclusions in the steel, such as brittle fractures that occur in some of the lesser-quality steels used in steel bars (such as ground steel) when bent at the processing site.

In the punching process on a thicker section, bending or repeated bending of the galvanized steel sheet with a smaller core radius results in an increase in the cold working stress. If a part is cracked due to strain aging, this cracking usually occurs directly after hot-plating, but for steel bars, it may also occur at the construction site, even if it is simply a stress generated by handling, it is enough to cause strain. Ageing brittle cracking.

Steel cracking occurs shortly after hot plating is completed, which is the biggest difference between strain aging brittleness and hydrogen embrittlement.